Carbon nanotubes are incredible things. They can be stronger than steel while being thinner than a human hair.

They are also highly stable, lightweight, and have incredible electrical, thermal and mechanical properties. For this reason, they hold the potential for the development of many interesting future materials.

They may also hold the key to building the materials and structures of the future, such as space elevators.

Here, we explore what they are, how they are made and what applications they tend to have. This is not meant to be an exhaustive guide and is only intended to be used as a quick overview.

RELATED: THESE CARBON NANOTUBES COULD POWER GADGETS THROUGH CLOTHING

What are carbon nanotubes and their properties?

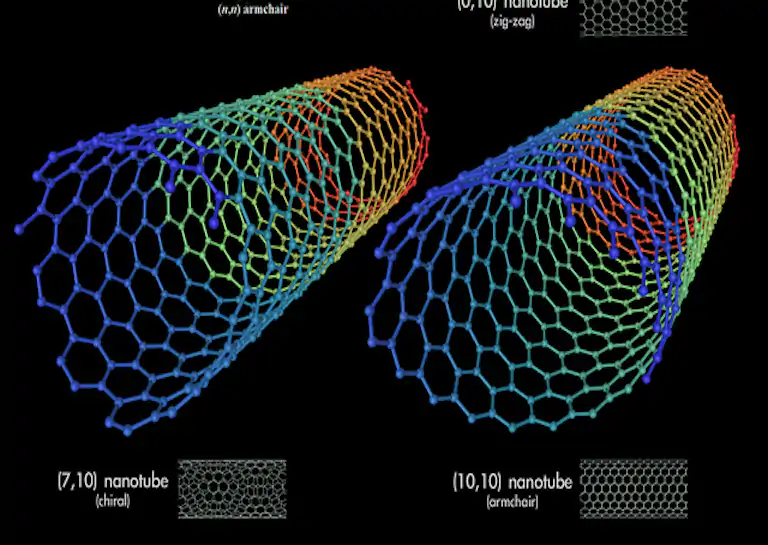

Carbon nanotubes (CNTs for short), as the name suggests, are minute cylindrical structures made from carbon. But not just any carbon, CNT's consist of rolled-up sheets of a single layer of carbon molecules called graphene.

They tend to come in two main forms (credit to nanowerk.com):

1. Single-walled carbon nanotubes (SWCNTs) - These tend to have a diameter of less than 1 nm.

2. Multiwalled carbon nanotubes (MWCNTs) - These consist of several concentrically-interlinked nanotubes and tend to have diameters that can reach in excess of 100 nm.

In either case, CNTs can have variable lengths from between several micrometers to centimeters.

As the tubes are exclusively built from graphene, they share many of its interesting properties. CNTs, for example, are bonded with sp2 bonds - these are extremely strong at the molecular level.

Carbon nanotubes also have the tendency to rope together via van der Waals forces. This provides them with high strength and low weight. They also tend to be highly electrically-conductive and thermally-conductive materials.

"Individual CNT walls can be metallic or semiconducting depending on the orientation of the lattice with respect to the tube axis, which is called chirality."

Carbon nanotubes also have other amazing thermal and mechanical properties that make them attractive for developing new materials.

For example (credit to nanowerk.com):

CNT's can have mechanical tensile strength 400 times that of regular steel.

They are very light-weight as their density is one-sixth of that of steel.

CNTs thermal conductivity is better than that of a diamond.

Carbon nanotubes have a very high aspect ratio of greater than 1000. In other words, in relation to their length, they are extremely thin.

"Their tip-surface area is near the theoretical limit (the smaller the tip-surface area, the more concentrated the electric field, and the greater the field enhancement factor).

Like graphite, they are highly chemically stable and resist virtually any chemical impact unless they are simultaneously exposed to high temperatures and oxygen - a property that makes them extremely resistant to corrosion.

Their hollow interior can be filled with various nanomaterials, separating and shielding them from the surrounding environment - a property that is extremely useful for nanomedicine applications like drug delivery."

What do carbon nanotubes do?

As we have already seen, carbon nanotubes have some very unusual properties. Because of this, CNTs have many interesting and varied applications.

In fact, as of 2013, according to Wikipedia via Science Direct, carbon nanotube production exceeded several thousand tons per year. These nanotubes have many applications, including use in:

- Energy storage solutions

- Device modeling

- Composite structures

- Automotive parts, including potentially in hydrogen fuel cell cars

- Boat hulls

- Sporting goods

- Water filters

- Thin-film electronics

- Coatings

- Actuators

- Electromagnetic shielding

- Textiles

- Biomedical applications, including tissue engineering of bone and muscle, chemical delivery, biosensors and more

There are also many promising areas in which carbon nanotubes could help in other exciting fields.

What are multiwalled carbon nanotubes?

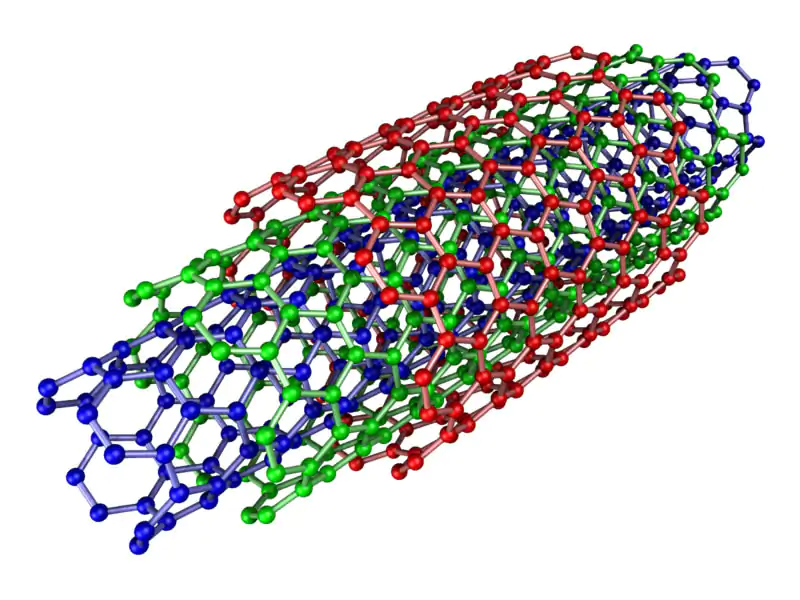

As we have already seen, multiwalled carbon nanotubes are those nanotubes made from several concentrically interlinked nanotubes. They tend to have diameters that can reach in excess of 100 nm.

They can reach in excess of centimeters in length and tend to have aspect ratios that vary between 10 and 10 million.

"They can be distinguished from single-walled carbon nanotubes on the basis of their multi-walled Russian-doll structure and rigidity, and form carbon nanofibers on the basis of their different wall structure, smaller outer diameter, and a hollow interior," notes Akos Kukovecz et al.

Multi-walled nanotubes can contain between 6 and 25 or more concentric walls.

MWCNTs have some excellent properties which can be exploited in a large number of commercial applications. These include (credit to azonona.com):

Electrical: MWNTs are highly conductive when properly integrated into a composite structure. It should be noted that the outer wall alone is conducting, the inner walls are not instrumental to conductivity.

Morphology: MWNTs have a high aspect ratio, with lengths typically more than 100 times the diameter, and in certain cases much higher. Their performance and application are based not just on aspect ratio, but also on the degree of entanglement and the straightness of the tubes, which in turn is a function of both the degree and dimension of defects in the tubes.

Physical: Defect-free, individual, MWNTs have excellent tensile strength and when integrated into a composite, such as a thermoplastic or thermoset compounds, can significantly increase its strength.

Thermal: MWNTs have thermal stability more than 600 °C, based on the level of defects and to a certain extent on the purity, as a residual catalyst in the product can also catalyze decomposition.

Chemical: MWNTs are an allotrope of sp2 hybridized carbon, similar to graphite and fullerenes, and as such have high chemical stability. However, one can functionalize the nanotubes to enhance both the strength and dispersibility of composites.

How are carbon nanotubes formed?

To date, there are three main methods for producing carbon nanotubes.

These are:

1. Arc discharge

Within this process, graphite is combusted electronically. CNTs form in the gaseous phase, which is later separated out.

This process also tends to use a metal such as iron, cobalt or nickel as a catalyst.

2. Laser ablation of graphite

Much like arc discharge above, graphite is combusted, except this time with the use of a laser. The CNT's form in a similar fashion and are also later separated out.

This technique also uses metal catalysts to facilitate the process.

3. Plasma torch

Similar to the first two methods above, the process to make a plasma torch makes use of carbon-containing gas instead of graphite vapors to create the carbon nanotubes.

4. Chemical vapor deposition (CVD)

CVD is a process that holds the greatest promise for the production of CNTs. It allows a much greater quantitative production process and is much more controllable.

It is also cheaper.

During CVD, a substrate is prepared with a layer of metal catalyst particles, most commonly nickel, cobalt, iron, or a combination.

"Nanotubes grow at the sites of the metal catalyst; the carbon-containing gas is broken apart at the surface of the catalyst particle, and the carbon is transported to the edges of the particle, where it forms the nanotubes," notes an edited volume on Chemical Functionalization of Carbon Nanomaterials.

This process can be purely catalytic or plasma-supported.

5. Liquid electrolysis

This technique was discovered in 2015 by George Washington University to produce MWCNTs through electrolysis of molten carbonates. The basic process is similar to that of CVD.